Accelerating innovation in eco-friendly material brand value with mushroom mycelium 'CELMURE'

RHOMBUS·PCLM (EDGE) Realizing ESG Value with a Resource-Circulating Biofactory

Beyond simply being an "eco-friendly company," creating a new industrial ecosystem where materials become brands.

Throughout the interview, MyCell's Business Strategy Group Leader, Jihyun Jeong, repeatedly emphasized "sustainability" and "innovation." He currently oversees MyCell's global growth strategy.

From Hyundai Motor Spinoff to Global Biomaterials Innovation Company: The Origins and Vision of 'MyCell'

MyCell was an early pioneer in discovering the limitless potential of mushroom mycelium. Specifically, its rapid growth rate and diverse transformation potential offered a solution that transcended the limitations of the existing materials industry.

Since its founding, MyCell has embraced "a virtuous cycle of environmental issues and material innovation" as its core value. Leveraging the infrastructure of a large corporation's in-house venture system, a youthful and flexible organizational culture, and intensive bio R&D capabilities, the company has grown rapidly. Beginning in a small laboratory, MyCell now collaborates with global high-end fashion and mobility brands in Europe and North America, earning recognition for its technological prowess and reliability.

MyCell is an eco-friendly startup that uses mushroom mycelia and fungi to create industrial and food materials, such as meat substitutes and leather substitutes. The company directly manages everything from raw material cultivation to materialization research, equipment development, and mass production. Notably, leather made from mushroom mycelia boasts exceptional properties, indistinguishable from natural leather. It also drastically reduces water usage during processing, and waste is biodegradable. MyCell's mushroom and fungal-based materials offer significant scalability for a variety of industrial applications, enabling the creation of a diverse portfolio of materials from a single production line.

Group Leader Jeong stated, “MyCell’s goal is not simply to be an ‘eco-friendly’ company, but to become a global standard company that creates real ‘environmental impact’ and industrial social innovation,” and expressed his ambition, saying, “We will continue to provide responsible leadership so that innovative technologies can result in sustainable social value.”

Beyond the perfection of the technology itself, Group Leader Jeong constantly considers how it can positively impact the environment and society and transform the entire industry's value chain. This is why "MyCell" aims to transcend the role of a simple materials company and propose a new paradigm: "Regeneration."

Premium biomaterial 'CELMURE' achieves both performance and environmental value.

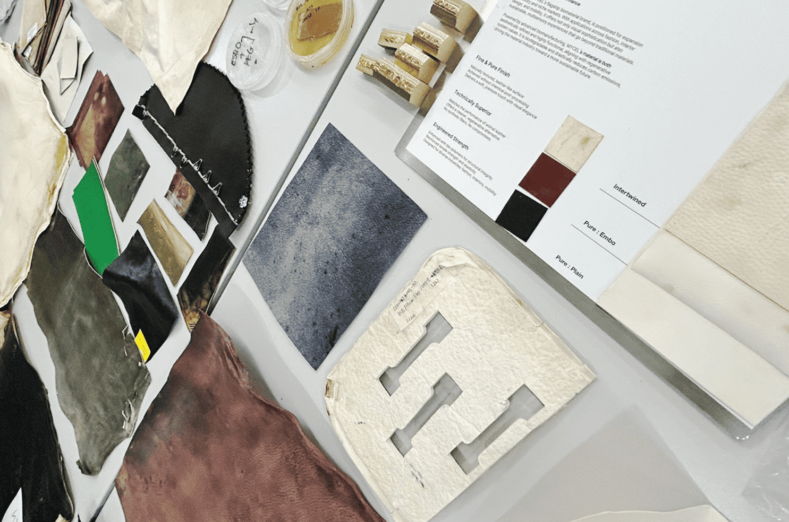

'CELMURE', the representative eco-friendly premium bio material of 'MyCell', is a 100% non-animal leather substitute material based on mushroom mycelia, and can structurally complement the fundamental limitations of the existing material industry.

CELMURE is a bio-based material that combines plant byproducts and mycelia, biodegrading in the natural environment without microplastics or toxic residues. Group Leader Jeong explained, "Existing synthetic leathers are not free from the issue of microplastics, and natural leathers have been plagued by animal ethics and environmental pollution during the disposal process. However, CELMURE reduces the environmental burden at the disposal stage to zero and proactively addresses global 'end of life' environmental regulations, such as those in the EU."

MyCell's unique bioreactor and AI-based environmental technology enable precise control of key properties such as mycelia growth patterns, microstructure, strength, and thickness. Group Leader Jeong emphasized, "The mycelia growth process is like weaving fabric. AI monitors and controls this process in real time, realizing superior industrial performance such as touch, abrasion resistance, water resistance, and dyeability comparable to natural leather. Through this, we are securing a competitive edge not only in 'eco-friendliness' but also in 'performance.'"

CELMURE is a next-generation material that combines eco-friendliness, veganism, functionality, and aesthetic value. Its potential has already been proven through projects such as a demonstration consortium with global brands, including those in the European market. It supports a variety of colors, textures, and patterns to meet the diverse design needs of consumers and brands.

'MyCell' has built a portfolio of over 20 major patents, has obtained PETA, REACH, and USDA certifications, and plans to secure B Corp certification.

'RHOMBUS' and 'PCLM (EDGE)' Build a Regeneration Platform with Intelligent Circular Biofactories

The differentiated competitiveness of 'MyCell' goes beyond the material itself, and includes 'RHOMBUS' and 'PCLM (Post-Culture Liquid Media) (EDGE),' which are intelligent bio-factory and circular resource platforms.

RHOMBUS is a large-scale mycelium production infrastructure designed in collaboration with Lotte Innovation Co., Ltd. Group Leader Jeong stated, “Previously, mycelium cultivation was conducted through a pilot-level manual management system, which had limitations in quality uniformity and mass production. RHOMBUS is an environmental control system that utilizes an IoT and AI-based sensor network. It analyzes and controls process parameters such as temperature, humidity, and nutrient supply in real time, and is expected to dramatically improve ‘quality uniformity’ and ‘mass production efficiency.’ This is a core system that ensures industrial reliability and safety, and is a prerequisite for the scale-up of ‘MyCell.’”

"PCLM (EDGE)" is a circular bio-production platform that integrates upstream and downstream management. Group Leader Jeong stated, "Over 90% of the byproducts generated during our material production process are recycled into high-value soil conditioners and other resources. Wastewater is also reduced by more than a third through a recycling system." He explained, "This model not only reduces waste but also creates new value from byproducts."

Group Leader Jeong emphasized the specific operating method and value of PCLM (EDGE), saying, "For example, the remaining mushroom mycelia after they have fully grown are utilized as organic fertilizer, and this is achieved by partnering with local farmers. This diversifies operational risks and secures a diversified revenue structure. Furthermore, by commercializing production byproducts and linking them to soil restoration projects, it creates additional ESG value, such as restoring local ecosystems, and creates positive social impacts."

Beyond being a simple materials company, MyCell is designing an integrated regeneration system encompassing processes and ecological restoration. The RHOMBUS process, based on a smart biofactory, precisely controls mycelial growth, ensuring consistent quality and production stability, dramatically improving production efficiency. At the same time, PCLM technology plays a crucial role in promoting ecosystem restoration by utilizing post-cultivation residues for wastewater purification and soil restoration.

Group Leader Jeong expressed confidence, saying, “RHOMBUS and PCLM (EDGE) are the industry’s best benchmarks in terms of eco-friendliness, economy, and resource circulation,” and “They will present a new paradigm for the industry through integrated, scalable process innovation.”

Global Stage and Market Expansion Strategy

'MyCell' is making its presence known in the global market by showcasing its proven data and portfolio at numerous international exhibitions, including the Premier Vision Paris 2026 SS fair in February, the interior industry's CIFF 2025, Design Shanghai 2025, and VivaTech in March. In the second half of this year, the company plans to expand its participation in various domestic and international exhibitions, including New York Climate Tech, Paris Fashion Week FW (fashion), Zero One & Hyundai Motors (mobility), and more, thereby broadening the awareness of 'MyCell' as a unique material brand.

Group Leader Jeong stated, “MyCell’s market strategy is largely driven by three pillars. First, in line with strengthening eco-friendly regulations in major markets like the EU, we will proactively remove entry barriers by enhancing our material certification procedures and LCA assessment capabilities to enable immediate response. Second, we will diversify our product portfolio by developing industry-specific materials, encompassing alternative materials, building materials (insulation, sound-absorbing panels), automotive panels (mobility), and functional interior/living products. Third, we will pursue R&D based on global partnerships and open innovation, along with localizing materials, to create new market opportunities through cross-industry convergence solutions.”

Group Leader Jeong stated, “MyCell’s mid- to long-term vision is to enter the ‘global top 3 sustainable biomaterial platform’ and to establish itself as a ‘Total Regenerative Solution Provider’ that transcends industrial and regional boundaries.” He added, “By developing the two axes of realizing eco-friendly value and industrial expandability in a balanced manner, we will solidify MyCell’s unrivaled position in the global market.”

Beyond technological innovation, driving social value and a virtuous ecosystem cycle.

Beyond simply being an eco-friendly materials company, MyCell strives to contribute to realizing social value and revitalizing the industrial ecosystem. Recent examples include fostering future talent through industry-academia collaboration with the Korea Bio-Meister High School, establishing shared infrastructure with startups in similar and different industries, academia, and private and public institutions, and leading R&D open innovation initiatives.

Group Leader Jeong stated, "MyCell's sustainability innovation goes beyond simply eco-friendly materials and products. It aims for the harmonious development of 'technological innovation, talent development, and social responsibility.'" MyCell aims to become a leader in industrial restructuring through advanced materials technology, enhancing social impact through ESG initiatives, and ultimately, positively impacting the global industrial ecosystem.

"MyCell" is creating new standards by integrating philosophy and technology, industry and ecosystem into a single flow. From environmental protection to ecological restoration, from sustainability to regeneration, "MyCell" is transforming tomorrow's environment with today's technology. This challenge is now unfolding in earnest, extending beyond Europe and reaching the entire world.

You must be logged in to post a comment.