Creating safer industrial environments with technology for people.

Accidents involving heavy equipment in industrial settings have a high potential to lead to major disasters. In particular, irregularly shaped and sized loads are difficult to detect with existing sensors or AI technology, making them a major cause of collisions. A startup is working to address this "invisible danger."

FBOE has developed an innovative industrial safety solution that accurately recognizes the shape of changing loads in real time and predicts collision risks using proprietary unsupervised learning-based AI technology. We met with FBOE CEO Ahn Seong-moon, who prioritizes preventing industrial accidents under the core values of "people-centered," "site-centered," and "trust-centered."

A startup that began in a graduate school lab uncovers a real need in the industrial field.

CEO Ahn Sung-moon's entrepreneurship stemmed from his research in AI vision technology during his graduate school years. "While working on projects with various companies in graduate school, I saw the level of technology they needed and the potential of the market," he said. "I decided to start a business because I believed that selling our own technology to companies would have a significant chance of success."

Founded in July 2021, Proboy didn't initially enter the industrial safety market. Initially, it developed camera technology for autonomous vehicles. Later, recognizing the potential of "on-device AI," it shifted its focus to lightweight AI solutions. However, the market was not yet mature, and it struggled to convince the public of the technology's necessity. A key turning point came in 2023, when it won the "HD Hyundai Heavy Industries Safety Open Market" contest. This event led Proboy to fully focus on industrial safety starting in 2024, and it helped it identify the market most in need of its core technology.

Predicting collisions with "non-standard loads" using proprietary AI technology.

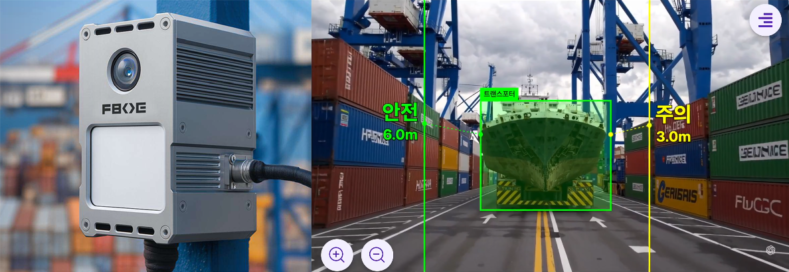

The core competitiveness of the Proboy solution lies in the combination of hardware and software.

Hardware Solutions

• Camera-Lidar Fusion Sensor: Equipped with a high waterproof and dustproof rating (IP67), it can withstand the harsh environments of industrial sites. In particular, the 'calibration' technology, which precisely matches the 2D plane camera coordinates and the 3D distance values (Lidar coordinates) using a self-developed AI algorithm, solved the problem of large errors in existing technologies. This allows for the generation of 3D camera images in real time, enabling accurate distance and shape recognition.

• Industrial Wireless Body Camera: With at least eight hours of continuous streaming on a single charge, it can be used throughout a shift. It also boasts a high water and dust resistance rating (IP65 or higher) and is constructed with an aluminum case, not plastic, to address overheating issues, ensuring reliable operation even in midsummer outdoor settings.

Of course, developing this innovative hardware for field use wasn't without its challenges. CEO Ahn recalled, "The biggest challenge was resolving the hardware's heat generation issue." He added, "We conducted numerous tests to address the issue of the equipment shutting down due to the intense heat of outdoor environments, and we have now secured stability."

Software (AI) solutions

• Unsupervised learning-based vision AI: Proboy's biggest differentiator is its ability to instantly detect diverse loads, such as pallets, steel plates, and ship blocks, whose shapes change constantly, without separate data labeling. CEO Ahn emphasized, "While our competitors can only predict collisions between heavy equipment, our greatest advantage is that we can even predict collisions with unpredictable loads."

• Artificial intelligence lightweight technology: Optimized to run high-performance AI models quickly and without delay on field devices, ensuring real-time performance.

Based on this technological prowess, Proboy is expanding its technology beyond simple collision prevention to a 'process analysis system' that analyzes the progress rate of ship blocks and other items by comparing the three-dimensional size data of the load with the drawing.

Proving technological prowess and expanding the market: "The ultimate goal is a collaborative signalman robot."

Proboy is rapidly demonstrating the practical applicability of its technology and achieving tangible results. It has successfully completed a Proof of Concept (PoC) with a major domestic heavy industry company and is currently expanding its applicability by simultaneously conducting technology demonstrations on various heavy equipment, including forklifts and transporters. Furthermore, it has been selected for the Korea Credit Guarantee Fund's "First Penguin" and TIPS programs, demonstrating its technological prowess and growth potential. Recently, after being featured on KBS1's "Documentary On" as a case study in industrial safety innovation, it has received numerous requests from various industries, including ports and construction, demonstrating strong market interest.

Having completed seed investment and selection as a "First Penguin" by the Korea Credit Guarantee Fund, Proboy is planning to secure Pre-A round investment to secure funds for hardware pre-purchase in accordance with the supply contract.

Proboy's short-term goal is to successfully complete the ongoing PoC for four types of heavy equipment—a forklift, transporter, and Goliath crane—and expand its application to multiple units. The long-term goal is to develop a "signalman collaborative robot." CEO Ahn stated, "The aging population and poor working conditions are creating a serious shortage of signalmen. We want to develop a robot that can follow heavy equipment in place of humans and detect hazards from a third-person perspective, thereby fundamentally solving the problem of human casualties."

Finally, CEO Ahn said, “Our solution has the advantage of being immediately applicable not only to heavy industry but also to any industrial site, including manufacturing, steel, and ports,” adding, “Ultimately, we will contribute to creating a safe industrial site for everyone by eliminating large-scale accidents that occur when moving heavy equipment.”

You must be logged in to post a comment.