– Applicable to various industries such as robotics, automobiles, and medical devices.

Next-generation silicone rubber that enhances the safety of electric vehicle batteries, eco-friendly liquid silicone rubber for food that does not require heat treatment, and lightweight, economical solid silicone rubber are introduced.

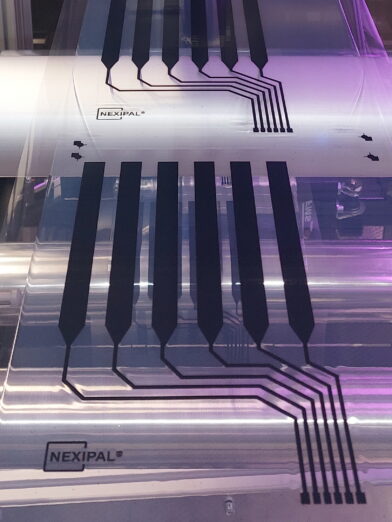

Global chemical company WACKER is entering the flexible electronics market in earnest by starting mass production of its flexible sensor electronics, 'NEXIPAL® Sense'.

It will be unveiled for the first time at the K-Show 2025 (International Plastics and Rubber Industry Exhibition) held in Düsseldorf, Germany from October 8th to 15th. In addition, the next-generation silicone rubber 'ELASTOSIL® R 531/60' with enhanced safety of electric vehicle batteries, 'ELASTOSIL® eco LR 5003', an eco-friendly liquid silicone rubber for food that does not require heat treatment, and 'POWERSIL® 1900 A/B', a lightweight and economical solid silicone rubber, will also be launched.

Nexipal Sense is constructed with a laminated structure of highly elastic silicone rubber films that possess both insulating and conductive properties. Its electrical capacitance changes depending on pressure or elastic deformation, generating precise sensor signals. It can be used in a variety of industries requiring precision measurement, including medical devices, robotics, and sports.

Through this mass production, Barker has expanded its business beyond simple material supply to become a sensor component manufacturer capable of customized, mass production.

Nexipal Sense is a laminated structure of films 20 to 200 microns thick, achieving precision comparable to the width of a human hair (approximately 50 microns). With near-self-healing resilience and high elasticity, it maintains stable performance even after millions of repeated deformations. It is also skin-friendly and biocompatible, operating reliably in environments ranging from -40°C to +180°C. The electrode layer is structured using Wacker-developed conductive silicon using digital laser printing technology, enabling precise patterns of less than 100 microns. Inline quality inspection using AI-based image analysis ensures uniformity of ±5 microns.

Elastosil R 531/60, a new silicone rubber for high-voltage electric vehicle batteries, is compatible with the extrusion process, facilitating efficient busbar insulation processes. Furthermore, in the event of a fire, the material forms a ceramic protective layer, preventing short circuits and enhancing the safety of electric vehicle occupants and rescue workers.

Elastosil Eco LR 5003, an eco-friendly liquid silicone rubber, meets product specifications for food containers and kitchenware without heat treatment (post-processing). Its biomethanol-based production saves resources. Furthermore, it can be applied to the liquid injection molding process, enabling the economical, high-volume production of a variety of household and food-related products, including straws, baking molds, and kitchenware.

POWERSIL 1900A/B, a high-performance silicone rubber (HCR), is a material for hollow-core insulators. This product is supplied in an additive curing process (A/B) and is suitable for the spiral extrusion process. Compared to conventional manufacturing methods, this process allows for the easier and more economical production of large insulators of various diameters. Furthermore, the final hollow insulators are lighter than conventional insulators, making transportation and installation much easier, with weight savings of up to 80% expected.

"Silicones play a crucial role in a wide range of industries due to their ease of processing and excellent mechanical properties," said Martin Bortenschlager, Head of the Silicones Business Unit at WACKER Engineering. "They enable technological innovation, particularly in high-performance sectors such as power grids, medical devices, e-mobility, and digitalization."

Barker operates an interactive exhibition zone in Hall 6 , A10 where visitors can experience firsthand.

You must be logged in to post a comment.