Measuring exactly how much carbon was emitted from each product produced in a manufacturing plant was nearly impossible. Large companies requested product-level carbon emissions data from their suppliers to meet the demands of their primary suppliers and global regulations, but most of the results were manual estimates.

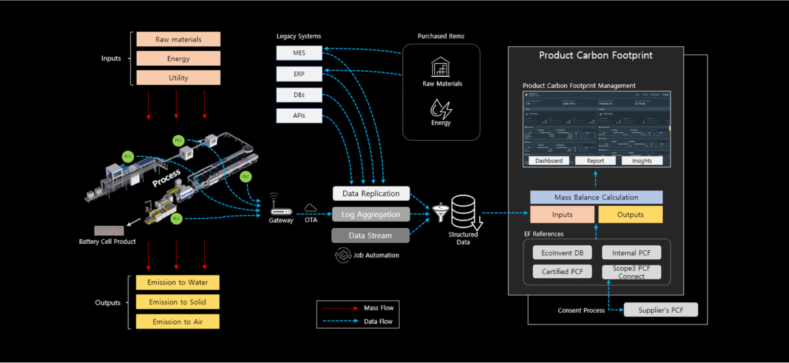

A technology developed by one company is changing this landscape. It is opening up an era where real-time carbon data can be collected and an accurate product carbon footprint can be calculated simply by connecting to factory equipment.

Product Carbon Footprint Solutions

Measuring your exact carbon footprint with data

“We offer two solutions: digital transformation solutions and carbon data management solutions.”

Founded in 2019 in Silicon Valley, Glassdom started out as a digital transformation solution centered on smart factories.

After joining Glassdom on the recommendation of a Silicon Valley investment firm, CEO Ham Jin-ki caught the pulse of ESG demands and global regulations. After six months of in-depth research, he discovered the market demand for ‘accurate product-unit carbon emissions calculation.’

Carbon regulations are moving from the business unit level to the product level, and companies need more precise information.

“This is our plug-and-play sensor. When you connect it to your equipment, it collects data in real time and automatically calculates your carbon emissions,” explained Ham Jin-ki, pointing to the device on the conference table.

Glass Dome Gateway

Solving Three Core Problems with Technology

Developing technology that is compatible with various controllers in manufacturing sites was a key task for GlassDome.

“The controllers in domestic manufacturing sites vary by brand and model, and their communication protocols are also diverse. We tested more than 50 industrial controllers and sensors over the course of about a year.”

The difficulty of technology development was revealed in CEO Ham Jin-gi’s explanation. The universal protocol interpretation and linking technology developed in this process became Glass Dome’s main technological strength.

There were three problems he found in the carbon management market: data inaccuracy, security issues with partner data, and the burden of certification costs.

“We have completed the cloud room system to prevent sensitive data from being disclosed to the main office. The partners store the data internally and only transmit the carbon footprint and certificate to the main office.”

There has also been notable progress in the process of obtaining ISO 14067 certification.

“We have ISO-certified the system itself to enable online pre-evaluation. Previously, verification was done through manual reports, so it took time to prove the reliability of the digital automatic calculation results.”

As a result, Glass Dome has achieved the result of reducing certification costs for its clients by approximately one-third compared to existing costs.

Enhancing the competitiveness of Korean technology on the global stage

After establishing a Korean corporation in 2020, Glassdom established a European corporation in Munich, Germany in January of this year.

“Europe is a center of carbon regulation and a market where institutionalization is progressing rapidly. Munich has excellent access to global manufacturing giants, including Siemens, and has the geographical advantage of easy travel throughout Europe.”

The partnership with Siemens signed in November last year is an example of Glassdome's technological prowess being recognized in the global market.

“By linking Siemens’ industrial software with Glassdome’s carbon emissions calculation technology, we have built a system that automatically calculates carbon emissions for each product in the automotive supply chain.”

Mr. Jin-ki Ham, who majored in mechanical engineering and nuclear engineering at Yonsei University and KAIST and was in charge of carbon regulation strategy at the Hyundai Heavy Industries Research Institute, is participating in the policy-making process as a member of the Presidential Committee on Carbon Neutrality and Green Growth. He is exploring new business opportunities in Vietnam and Japan and under the EU’s Digital Product Passport (DPP) system.

“Most small and medium-sized companies do not have dedicated ESG personnel and do not have their own IT systems. We want to support them so that they do not simply respond to regulations but use them as opportunities to secure global competitiveness.”

The real-time carbon reduction dashboard in the company lobby demonstrated Glassdome’s goal of visualizing and accurately measuring carbon data.

You must be logged in to post a comment.